|

|

Post by Fiveohmike on Sept 22, 2010 20:07:03 GMT -5

Hey Guys,

I bought the stinger return line for my SVO. I got it installed and made sure there were no kinks. I put the engine side in and then the turbo side.

When its like this the car smokes at idle.

I put the stock line back in (blows oil under boost) and no smoking at idle.

Any ideas or things to try?

|

|

|

|

Post by Stinger on Sept 22, 2010 22:39:59 GMT -5

Can you email me pics of it installed or post them here? In rare occasions this can happen when the turbine seal is a little weak. Most cases I've seen are related to installation issues though. Pictures normally tell the story.

|

|

|

|

Post by Fiveohmike on Sept 22, 2010 22:56:06 GMT -5

Ill post pics tommorrow once its light out again.

Thanks!

|

|

|

|

Post by Fiveohmike on Sept 23, 2010 14:56:41 GMT -5

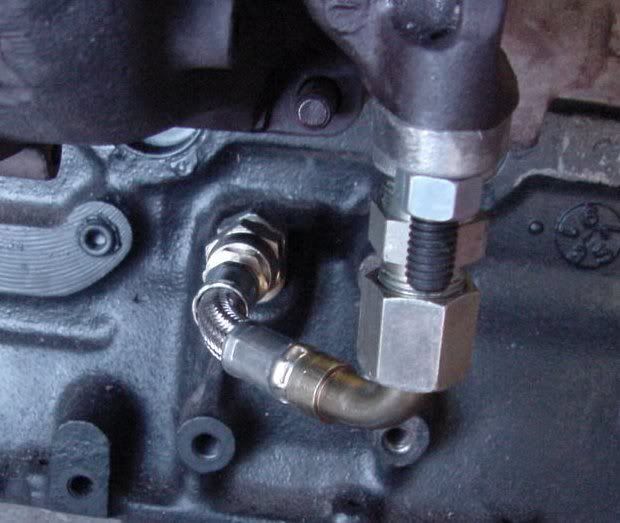

Here is the pic. The fitting just look too long and its goes up. The 45 fitting will not screw into the block anymore then that, and the flange site is tight as can be. Any thoughts?  |

|

|

|

Post by Stinger on Sept 24, 2010 17:38:18 GMT -5

Is it our flange? Did you use teflon tape? Is it an e6 manifold? Is it a stock turbo or has it been rebuilt or replaced? I bottom out the flanges by hand before shipping them so it seems odd that it's not bottomed out in the pic.

|

|

|

|

Post by Fiveohmike on Sept 24, 2010 18:13:02 GMT -5

Yep its your flange. Its a stock turbo, never been rebuilt, stock 85 Manifold. This shot is with no teflon tape ( i mounted it back just for the pic).

Which nut should be bottomed out on the flange side? The AN fitting nut ?

|

|

|

|

Post by Stinger on Sept 24, 2010 19:09:14 GMT -5

I looked at the pic again and it appears the fitting it is bottomed out in the flange. I'm currently out of town so I'm viewing the pic on my phone. When I get back in town I'll compare how far yours is threaded into the block to how far mine is. Everything else looks ok so I can't figure out why the line is so far out of vertical alignment.

The vertical alignment is dictated by the thread depth into the flange (bottomed out) the formed 90 in the line (fixed shape from parker fittings) and the thread depth into the block.

|

|

|

|

Post by wired4speed on Nov 4, 2010 15:05:50 GMT -5

i just ordered my second oil return line as severly kinked the first one... and though I tried to straighten it out, car blows much oil into the O2 housing.... I hope that this is figured out for reference ...

mike

|

|

|

|

Post by Stinger on Nov 4, 2010 22:40:32 GMT -5

I really have no idea (from the pic above) what is making that turbo nearly 1/2" lower than it should be. The two crimped areas of the line should be level with each other. If they aren't, the line shouldn't be tightened because it will be ruined as soon as it is stretched (like above) or kinked. Here is how it should look:  With that said, the ID of the line isn't ideal but it's as large as could be fitted in the small space the stock location dictates (according to MaxPSI who designed the line). Now that I bought MaxPSI out, I've been working on a -10 stock return line. After spending quite a bit of time and money on different configurations, I finally got it to work. It just requires a custom flange coming off the turbo (which I'm working on now). The catch is, it still won't work on a setup like is shown above where the turbo is somehow nearly 1/2" below what my factory engine "test mule" is. It will also have to be about $15 more expensive than the current line because the custom flange is twice the price and the larger -10 fittings/line are all more expensive than the current -8 stuff. Here is a look at the new -10 Stock Return line:  |

|

|

|

Post by wired4speed on Nov 8, 2010 21:07:17 GMT -5

just got my second one today, and it still isn't providing adequate drainage... now that you mentioned ID not being ideal... I had wondered that myself as the stock corrugated line is much larger in diameter... my installation looks just as your correct picture looks.

I am installing a borrowed stock tube tomorrow. If in fact the stock tube works, well then I guess this particular part isn't correctly designed, and well.... we'll see what happens tomorrow.

I am definitely interested in the larger diameter piece..

Hope you guys aren't upset I am posting in this thread...

|

|

|

|

Post by Stinger on Nov 8, 2010 23:52:57 GMT -5

There are a small percentage of people that don't have any luck getting the stock replacement return line to work for them without smoking issues. Many of them are installation errors, some of them aren't. That's why now that I have control over the lines "in-house", I'm working on a solution. I don't have any problem with you posting about it here.

|

|